Biogas

agenitor80 to 450 kW

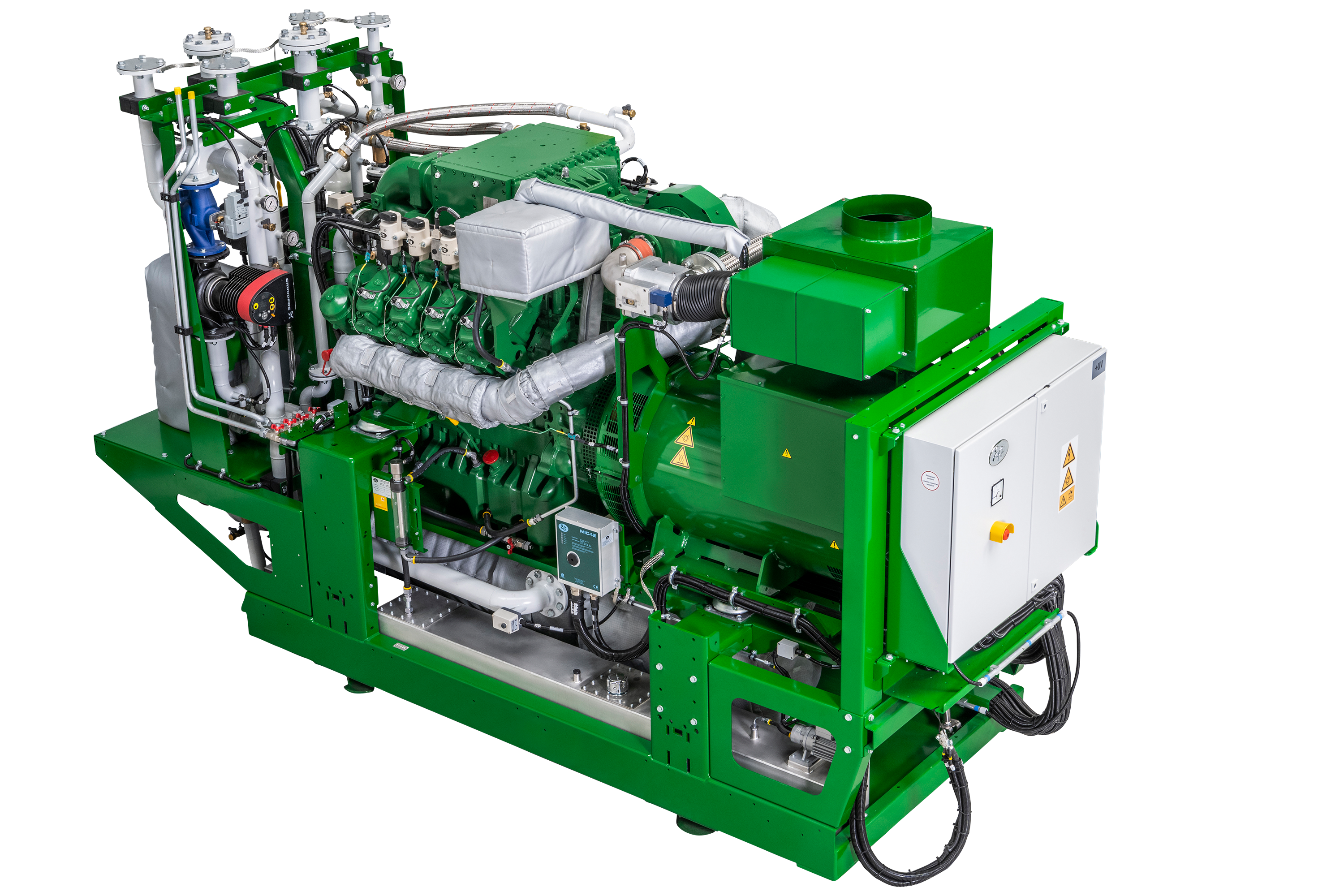

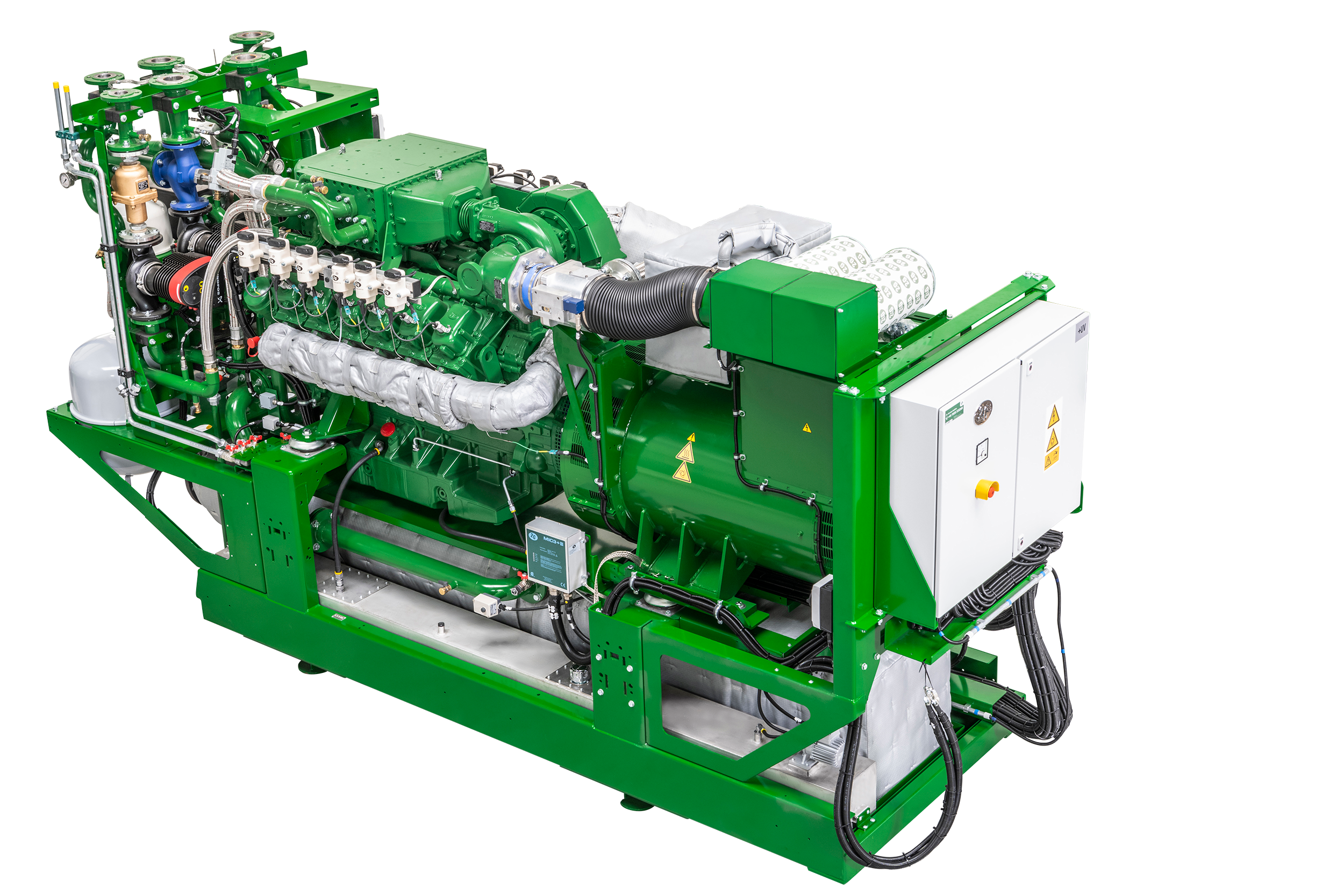

The agenitor by 2G results from intensive work by the 2G research and development team. Improving combustion chamber geometry has made it possible to increase the efficiency of the agenitor significantly.

- Highly efficient power plant with an optimized gas engine – and therefore lower fuel costs

- Modular design facilitates installation in hard-to-reach places

- Very reliable even in regular start-stop operation thanks to highly wear-resistant engine components

- Resilient and low-maintenance

- Available as a twin pack configuration with two modules per container for twice the power

Request a Quote | Download agenitor biogas brochure

Technical Details

Biogas

| Type | Output | Efficiency | |||

| electrical | thermal | electrical | thermal | total | |

| agenitor 404a | 80 kW | 341 MBTU | 35.2 % | 44.1 % | 79.3 % |

| agenitor 404b | 100 kW | 406 MBTU | 37.0 % | 44.0 % | 81.0 % |

| agenitor 404c | 160 kW | 580 MBTU | 39.7 % | 42.0 % | 81.7 % |

| agenitor 406 | 250 kW | 887 MBTU | 41.3 % | 42.9 % | 84.2 % |

| agenitor 408 | 360 kW | 1,306 MBTU | 40.9 % | 43.6 % | 84.4 % |

| agenitor 412 | 450 kW | 1,555 MBTU | 40.2 % | 40.8 % | 81.0 % |

avus550 to 2,500 kW

The avus is a highly efficient 2G power plant for high electric power consumption (above 500 kW), which is used in larger industrial projects or for supplying microgrids. The modular built systems include all components and are easy to install.

- Interconnection of multiple units allows for higher electrical output. A Master Control system enables synchronization and load sharing to up to 5 modules.

- Efficient running mode and operating times due to excellent engine quality

Request a Quote | Download avus biogas brochure

Technical Details

Biogas

| Type | Output | Efficiency | |||

| electrical | thermal | electrical | thermal | total | |

| avus 500 plus | 550 kW | 2,002 MBTU | 40.6% | 43.3 % | 83.9 % |

| avus 600c | 600 kW | 2,190 MBTU | 40.4 % | 43.1 % | 83.5 % |

| avus 800c | 800 kW | 2,859 MBTU | 40.7 % | 42.7 % | 83.4 % |

| avus 1200c | 1,200 kW | 3,900 MBTU | 42.8 % | 40.7 % | 83.5 % |

| avus 1200d | 1,145 kW | 3,979 MBTU | 41.5 % | 42.3 % | 83.8 % |

| avus 1500c | 1,560 kW | 5,374 MBTU | 41.7 % | 42.1 % | 83.8 % |

| avus 2000c | 2,000 kW | 6,817 MBTU | 42.3 % | 42.2 % | 84.5 % |

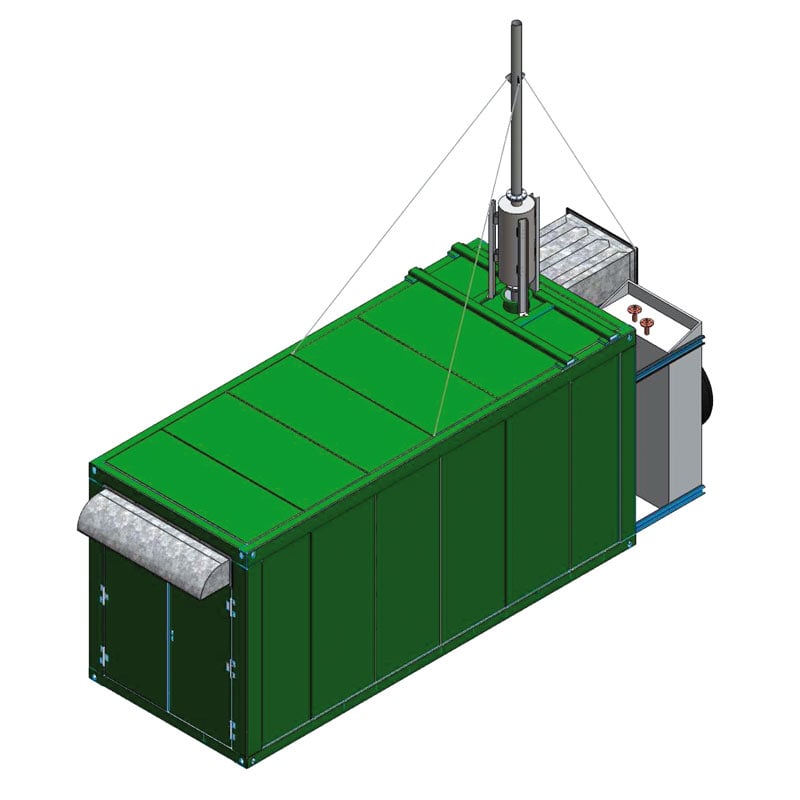

Containerized Solutions

2G power plants can be installed in various ways – depending on local conditions and the requirements for sound insulation. They can therefore be incorporated in existing buildings or heating systems or can be set up separately in a container or engine room. With the appropriate sound insulation package, noise emission can be as low as 35 dB (A) at a distance of 10 m.

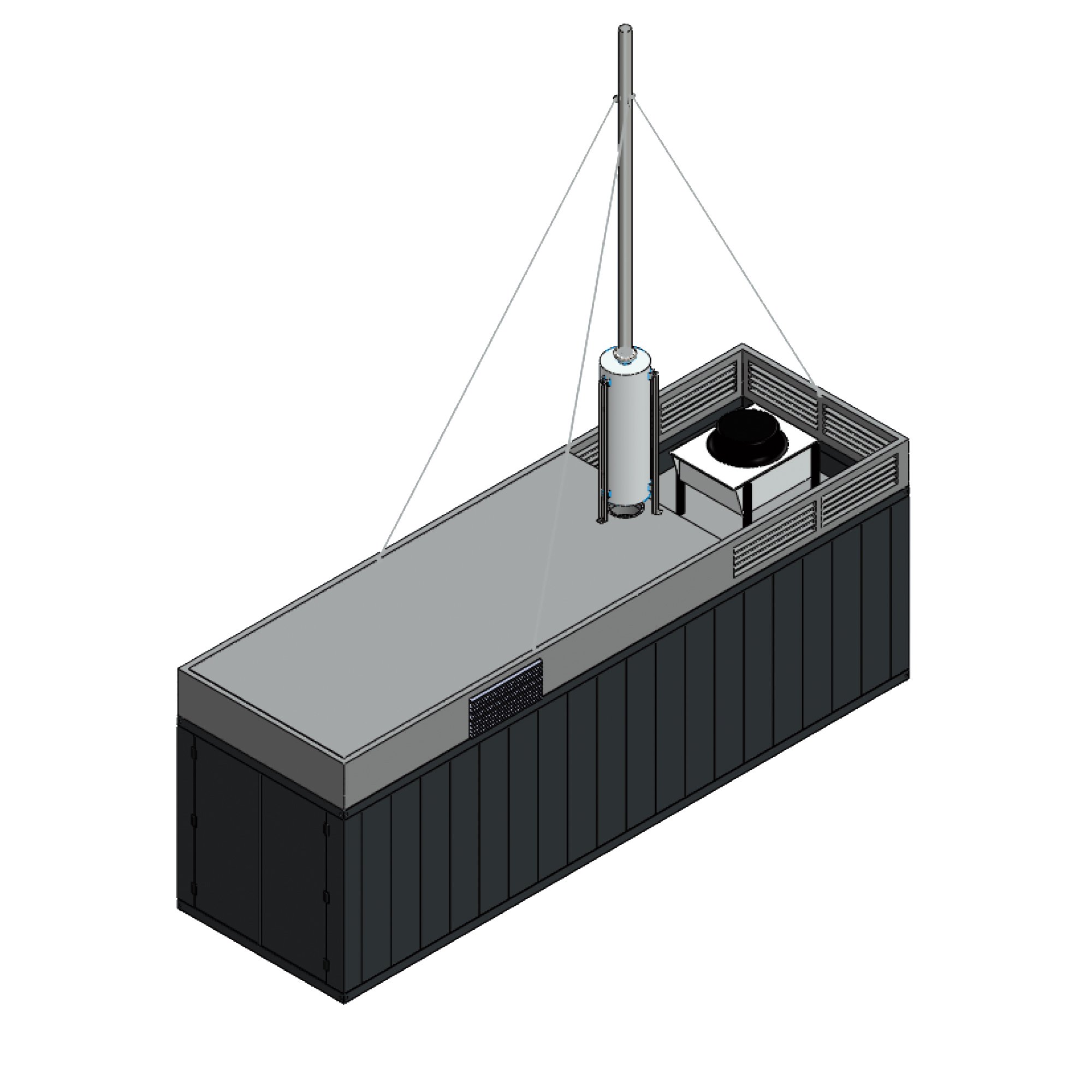

Compact Container

Sizes Available

Sizes Available

19.7 ft x 8 ft x 9.5 ft

Acoustic Emissions

Standard: 65 dB (A)

Super silent: up to 55 dB (A)

Standard Container

Sizes Available

Sizes Available

22.9 ft x 9.8 ft x 9.8 ft

31.5 ft x 9.8 ft x 9.8 ft

Acoustic Emissions

Standard: 65 dB (A)

Super silent: up to 52 dB (A)

Highline Container

Sizes Available

Sizes Available

29.5 ft x 9.8 ft x 12.1 ft

34.4 ft x 9.8 ft x 12.1 ft

39.4 ft x 9.8 ft x 12.1 ft

39.4 ft x 14.1 ft x 17.5 ft

Acoustic Emissions

Standard: 65 dB (A)

Super silent: up to 45 dB (A)

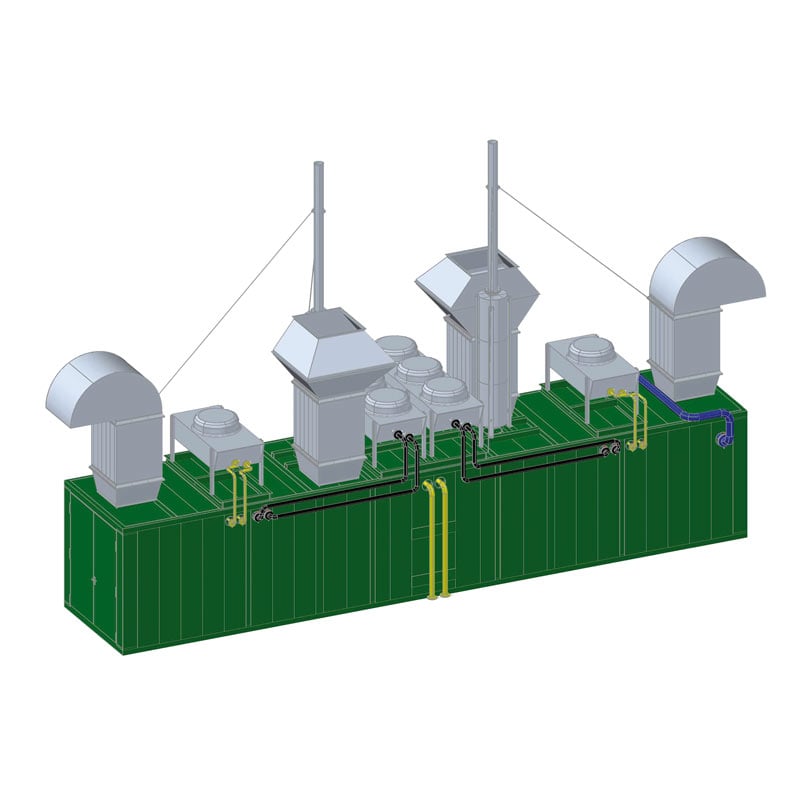

Twinpack Container

Sizes Available

42.7 ft x 9.8 ft x 9.8 ft

49.2 ft x 9.8 ft x 9.8 ft

Acoustic Emissions

Standard: 65 dB (A)

Super silent: up to 52 dB (A)

Heavy Container

Sizes Available

39.4 ft x 9.8 ft x 9.8 ft

49.2 ft x 9.8 ft x 9.8 ft

55.8 ft x 9.8 ft x 11.2 ft

Acoustic Emissions

Standard: 65 dB (A)

Super Silent: up to 52 dB (A)

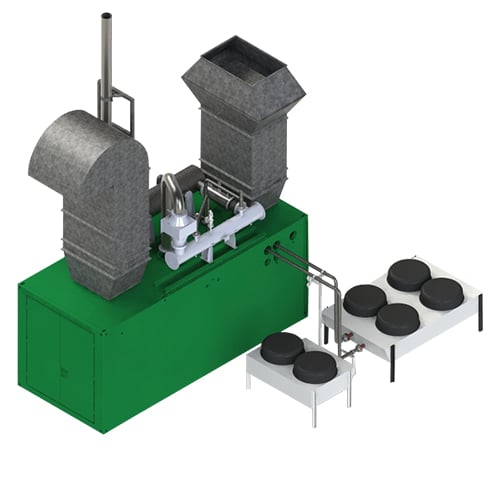

Outdoor Sound Capsule

Sizes Available

Sizes Available

Depending on product

Acoustic Emissions

Standard: 65 dB (A)

Sound Capsule

Sizes Available

Sizes Available

Depending on product

Acoustic Emissions

Standard: 65 dB (A)

Biogas Case Studies

Stanton Farms - London, Ontario, Canada

From how they cool the milk using a combination of earth energy and unique heat-exchange technology to converting on-farm organic waste to renewable energy to power up the neighboring community, Stanton Farms is always looking to close the loop in every aspect of their operation. Family-owned and operated by Laurie Stanton and his wife Sandy, along with their children Jeff, Jim, Greg, and Amy, Stanton Farms is the largest of six agricultural biogas facilities in Ontario. Stanton Farms has 2000 dairy cattle, including those used for dairy production and a genetics and breeding operation. Each cow generates 4 kW/day of renewable energy from the manure they produce.

DariTech - Tillamook, OR, USA

The Port of Tillamook Bay (POTB), a 1,600-acre industrial park on the Oregon coast, ordered a complete $5.6 million manure anaerobic digester from DARITECH, including a highly efficient 1.2 MW 2G avus biogas CHP system. The fully integrated prime mover of the CHP System is a 2G avus 1200 with an MWM core engine and a capacity of 1,200 ekW/h or 9,960 MW p.a. electrical power and 1,225 kWh of thermal power. In addition to the CHP unit, 2G Energy Inc. supplied the complete gas treatment, including a cooler, dryer/dehumidifier, and the H2S removal system.

Region of Waterloo Waste Water Treatment Plants - Ontario, Canada

The Region of Waterloo Waste Water Treatment Plant CHP sites has been active for many years. It is estimated that the anaerobic digesters at the existing WWTP in Waterloo alone produce 4,000 to 7,000 cubic meters (m3) of biogas daily. The electrical power produced is consumed within the WWTP's, offsetting power purchases to operate the plant. The heat produced by the engines is used to heat incoming sludge to the digesters and heat the digester buildings when required (mainly in the winter).